TOWING TANK ETSIN

The Model Basin Facilities is the scenario where the practice classes of the MAERM are carried out. The towing tank with a dimensions of 100m length, 3,8m wide and 2,2 m deep, has a wave generator of regular and irregular waves and any hydrodynamic test can be done on ship and offshore structures models. During the classes, “the Stabiliy test”, “resistance test”, “extinction test”, “seakeeping test” and the set-up of the different tests are done.

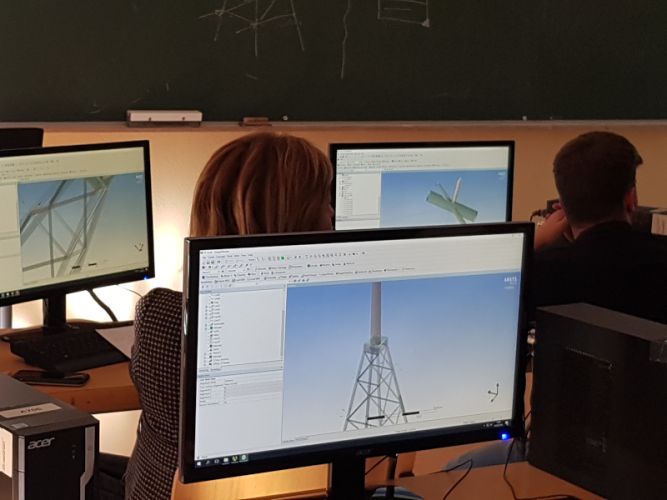

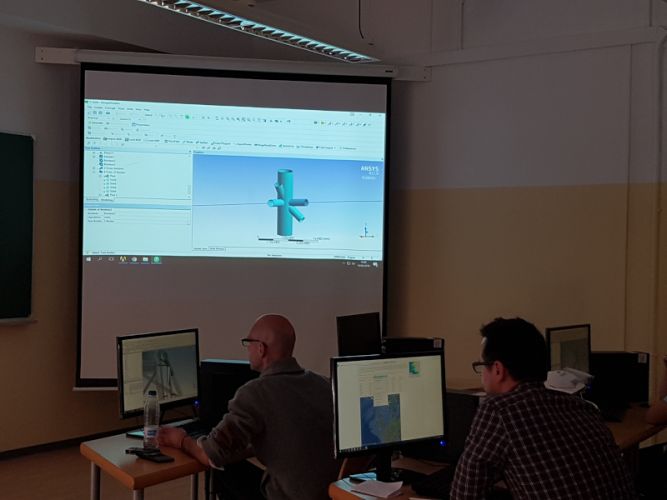

COMPUTING CENTER

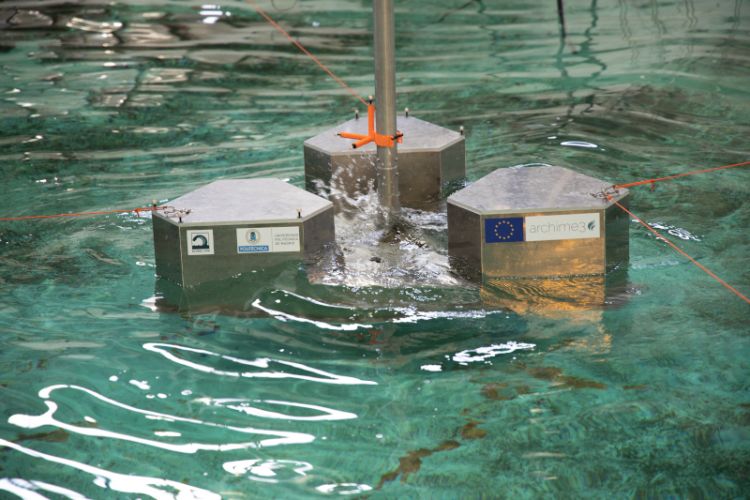

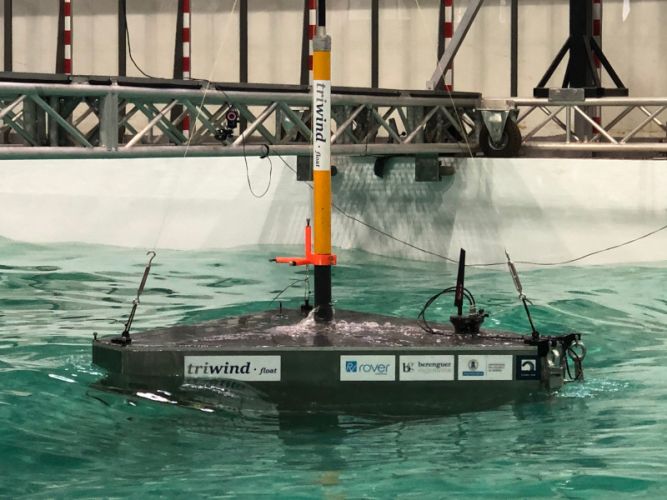

MULTIDIRECTIONAL SURGE TANK ETSICCP

The surge tank is the central facility of the laboratory. Small-scale tests of different infrastructures are carried out here, whether they are coastal and offshore, both anchored and floating.

Thanks to its great versatility and state-of-the-art generation and acquisition equipment, numerous sea states can be simulated in it.

| Characteristic

Dimensions: 33m x 11m x 1.36m |

Multidirectional generation

The generation of multidirectional waves is carried out by means of 16 piston-type blades with active absorption of reflected waves manufactured by HR Wallingford. The system is capable of generating up to 0.30 m wave height with a period of 4 s |

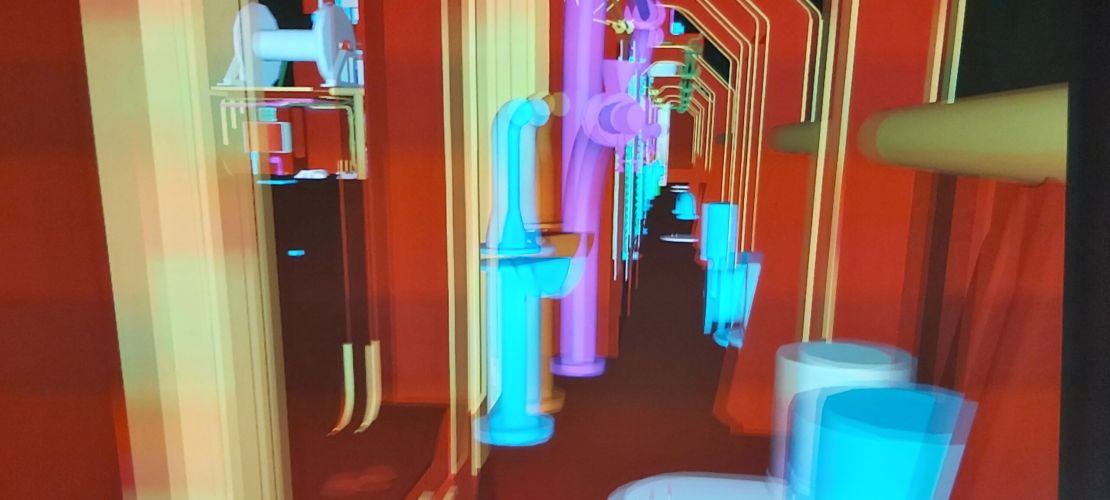

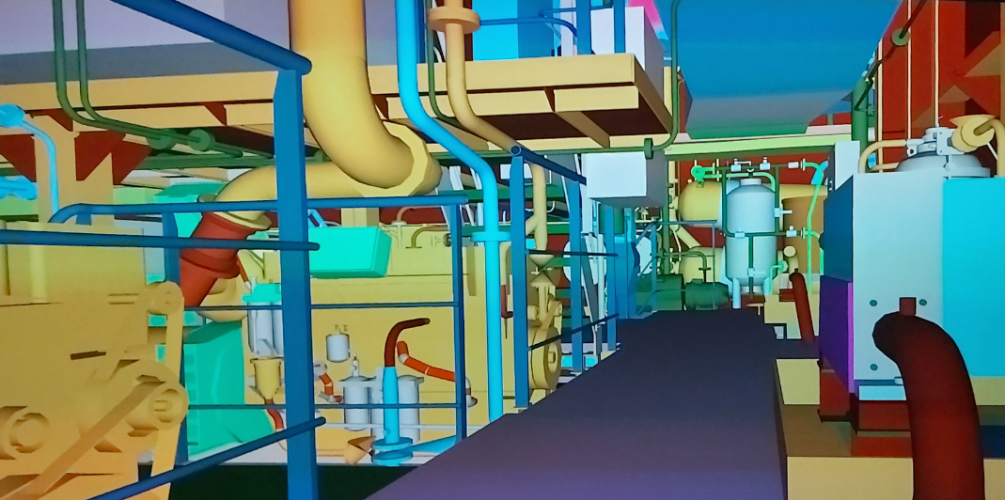

MAERM Virtual Reality Cave

The Virtual Reality solution is very useful for the MAERM students because immersive real-time access solutions to review the 3D virtual model of a supply ship, or a wind farm, for example, are currently of great importance, among other things due to it allows students (and future engineers and operators) to become familiar with shipbuilding without the cost or danger of doing so in situ.

The Virtual Reality solution of the ETSIN allows access to the 3D model of the ship or wind platform, and this will give the students the ability to review the virtual model, facilitate the visualization and navigation through it, in addition to assist for other typical naval sector jobs: design review, operations simulations, ergonomics and marketing.

The ETSIN´s Virtual Reality cave will allow, among other functions, to walk through the model in real time, make queries about properties and attributes, detect, and manage collisions, make annotations, measure margins and distances and carry out ergonomic studies. In addition to the software, the Virtual Reality solution also covers the creation, installation, and configuration of visualization environments for adapting to the most complex demands and requirements.

The Virtual Reality solution that we have installed in the ETSIN can be applied in technical design and review, manufacturing, development and planning processes in interactive and collaborative environments, in such a way that it has the following main characteristics:

- Solving complex design or manufacturing problems in an educational and collaborative environment.

- Validation of complex assembly processes.

- Prototypes, variants, and virtual configurations to achieve the final design.

- Detection of design errors.

- Improvement of production and maintenance operations.

- Ergonomics studies (accessibility and ease of use).

- Training of future assembly operators.

- Training of future personnel in ships and offshore platforms.

This solution gives the user the possibility, not only to look at the model, but also to walk through it in real time and to query about the properties and technological data of the different ship’s components.

It is possible to use multiple lights and to assign special properties to surfaces, like texture or translucency. It is also possible to simulate maintenance operations by defining paths, moving, and rotating elements of the scene along these paths. In addition, ergonomics of the design can be checked by importing in the scene human models.

The viewing control is performed by direct mouse or joystick manipulation and supports different navigation modes. Other capabilities are:

- Selection of components by different criteria.

- Operation with groups of selected items.

- Interference checking.

- Measurement between items.

- Addition of notes.

- Remember camera position.

- Camera and objects paths manager.